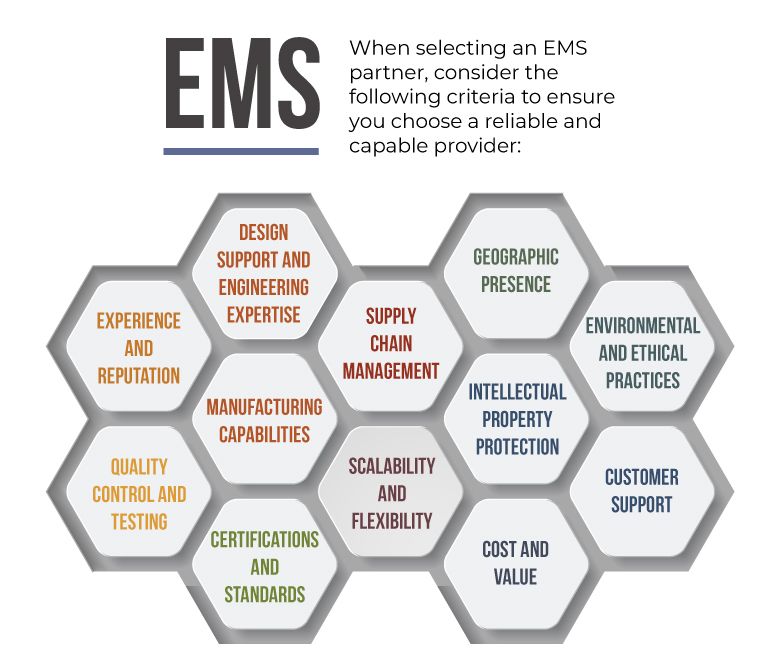

Criteria for evaluating EMS (Electronic Manufacturing Services) providers

Electronic Manufacturing Services (EMS) refer to the outsourcing of electronic product design, manufacturing, assembly, testing, and sometimes, after-sales services to specialized third-party companies. EMS providers are contract manufacturers that offer a wide range of services to support the production of electronic components, sub-assemblies, and complete products on behalf of original equipment manufacturers (OEMs) or other companies.

Electronic Manufacturing Services are widely used across various industries, including consumer electronics, automotive, aerospace, telecommunications, healthcare, and industrial equipment manufacturing. By leveraging the expertise and capabilities of EMS providers, companies can benefit from cost-effectiveness, access to advanced manufacturing technologies, and scalability while focusing on their core competencies like product development and marketing.

|

Experience and Reputation: Look for an EMS provider with a proven track record and a good reputation in the industry. Check their portfolio and customer testimonials to gauge their experience and customer satisfaction. |

|

Scalability and Flexibility: Consider the EMS provider's capacity to scale production to meet your volume requirements. They should be able to accommodate fluctuations in demand and adapt to your business needs. |

|

Certifications and Standards: Ensure that the EMS provider complies with industry standards and certifications, such as ISO 9001 (quality management system), IATF 16949, or VDA 6.3 (automotive related device). These certifications demonstrate their commitment to quality and adherence to best practices. |

|

Geographic Presence: Depending on your product's market and distribution requirements, consider the EMS provider's global presence and the ability to manufacture in different regions. |

|

Manufacturing Capabilities: Assess the EMS provider's manufacturing capabilities, including the type of electronic components they can handle (surface mount technology, through-hole, etc.), PCB assembly technologies, and any specialized services they offer. |

|

Intellectual Property Protection: If your product design is proprietary, ensure that the EMS provider has proper security measures in place to protect your intellectual property. |

|

Quality Control and Testing: Inquire about the EMS provider's quality control processes and testing procedures. A good EMS partner should have robust quality control measures in place to ensure the reliability and functionality of the manufactured products. |

|

Cost and Value: While cost is a crucial factor, focus on the value proposition offered by the EMS provider. Consider their overall capabilities, quality, and reliability in addition to the pricing. |

|

Supply Chain Management: Evaluate the EMS provider's supply chain management capabilities. A reliable partner should have a well-established supply chain network to source electronic components and materials efficiently. |

|

Customer Support: Assess the EMS provider's responsiveness and customer support. Effective communication and support are essential for a successful partnership. |

|

Design Support and Engineering Expertise: If you require design support or assistance with product engineering, ensure that the EMS provider has skilled engineers and design capabilities to meet your needs. |

|

Environmental and Ethical Practices: Consider the EMS provider's commitment to environmental sustainability and ethical business practices. Companies with eco-friendly initiatives and responsible supply chain practices can align better with your values. |

By carefully evaluating EMS providers based on these criteria, you can select a reliable partner that aligns with your business needs and contributes to the success of your electronic product development and manufacturing process.