Industrial Metaverse

Embrace the era of unified experiences, as we pave the way for a transformative and interconnected future in the metaverse.

In the dynamic realm of industrial operations, a transformative shift is occurring as on-site operators and technical teams embrace advanced communication technologies. This seamless collaboration allows swift issue resolution, minimizing downtime and optimizing system performance. Simultaneously, on-site workers utilize cutting-edge AI identification systems to monitor machinery. Instant access to comprehensive performance data empowers precise maintenance execution, aligning corrective actions with equipment needs. This integration of human expertise and technology promises enhanced efficiency and longevity, shaping the future of responsive and sustainable industrial practices.

|

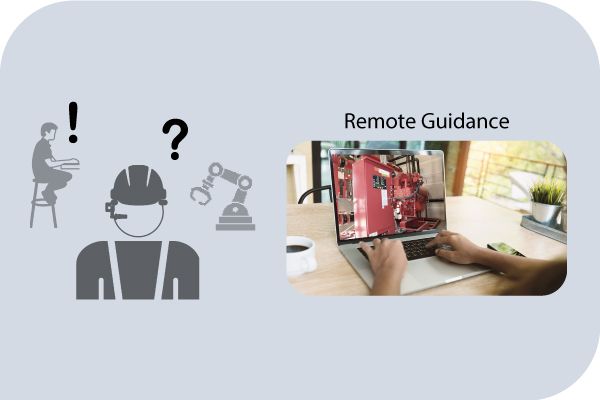

Remote Collaboration

On-site operators and technical teams seamlessly engage in remote collaboration, leveraging advanced communication technologies and collaborative tools to swiftly address issues and restore the system to its optimal operational state. This streamlined collaboration ensures a rapid response to challenges, promoting efficiency and minimizing downtime in achieving the prompt resolution of technical issues. |

|

|

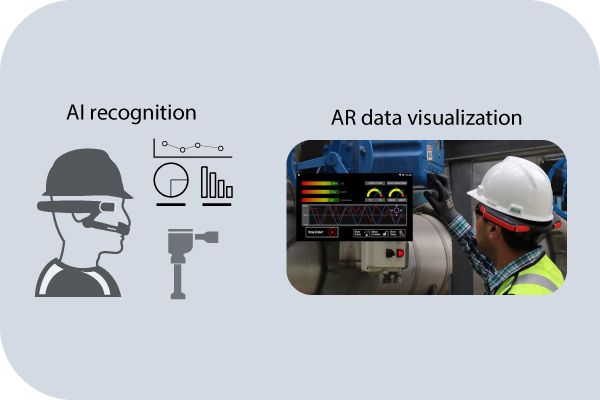

AI/AR

On-site workers diligently monitor the machinery, utilizing state-of-the-art AI identification systems. With the ability to instantly visualize comprehensive performance data, they are empowered to carry out maintenance tasks with precision, ensuring that corrective actions are aligned seamlessly with the specific needs of the equipment. This integrated approach not only enhances the efficiency of maintenance work but also contributes to the overall optimization of machine performance and longevity. |

|

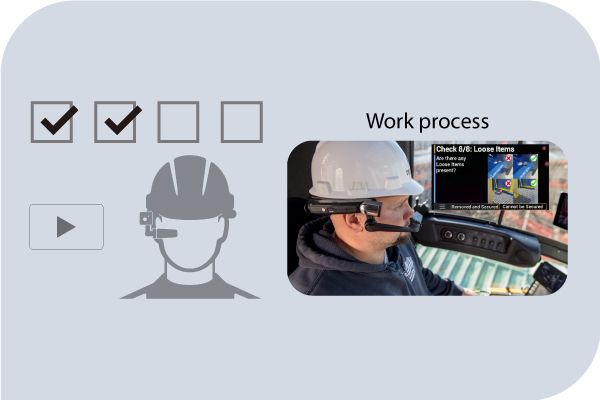

Work Process

On-site workers have the capability to swiftly log in to the system and acquire proficiency in new inspection procedures. Guided by comprehensive work instruction videos, employees can effortlessly navigate through the various steps pertaining to mechanical equipment, ensuring a seamless and efficient execution of tasks. This user-friendly approach facilitates a quick and effective learning process, enabling workers to stay abreast of updated procedures and carry out their responsibilities with confidence and accuracy. |

|

|

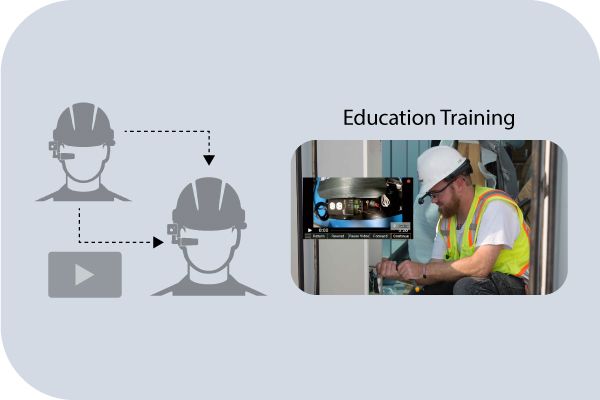

Training and Education

On-site workers capture first-person video content while performing maintenance tasks, documenting each step of the process. This footage is then uploaded to the digital work platform, serving as a valuable reference standard for future procedures. By leveraging this recorded material, teams can enhance collaboration, share insights, and ensure consistency in the execution of maintenance work. The availability of such visual references on the digital work platform streamlines training, facilitates knowledge transfer, and contributes to the creation of a comprehensive repository for ongoing improvement and optimization of maintenance practices. |

| Experience Better Viewability | Rugged Design | PPE Compatible |

| evolutionary Modular Design | High-resolution camera | Full-shift |

| Enhanced Remote Collaboration |